Description

As a Professional Factory for producing Extrusion Blow Mould more than 15 years in China, with annual capacity hundreds of molds to meet different industries‘ packaging needs.

Order Process for Extrusion Blowing Molds:

1 Basic Information Required

First of all, we need basic information of the bottle you required.

Bottle / hollow product information needed:

Raw material, capacity / volume, shape

Neck size, weight, dimension, application

Your extrusion blow molding machine information needed:

double station or single station

die head number(mold cavity number)

center distance of die head

with or without Auto Deflashing

If you don’t have an idea, we will discuss your needs, purpose and objective thoroughly and provide a concept that will satisfy your situation. We will work with you from the ground up.

2 Bottle & Hollow Product Design

The next step is to take the basic or idea and workup both 2D and 3D drawing detailing all the features. Following the drawings we then digitize the new bottle and render it out for a very close approximation of what the final bottle will look like. This is where it really starts to come to life.

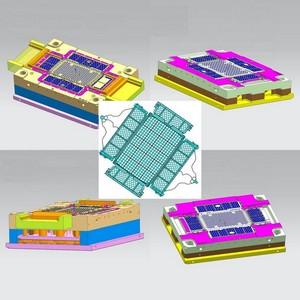

3 Extrusion Blow Mold Design

After you confirm the bottle drawing or 3D sample, we start make mold design based on our extrusion blow molding machine or your machine parameters.

4 Extrusion Blow Mould Fabrication

Next, we take the drawing to start mold manufacturing. It usually takes 30 days to get the mold done.

5 Extrusion Blow Mold Test

Now we can do the mold trial and send you real samples for final confirmation. This is where your ideal bottle becomes a reality.

6 Mold Shipping Or Mass Production

The last step is deliver the mold to you. We can provide both of air & sea shipment with economical cost. Or if you want the bottles / hollow products only, we can do the mass manufacturing for you.

English

English Español

Español Português

Português