Description

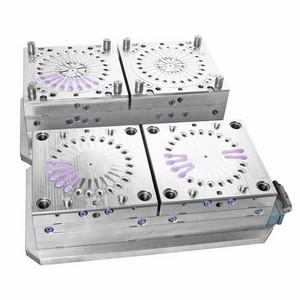

We are one of the leading Manufacturers of Plastic Knife Mould and can also customize the mold according to client’s requirements. Our PP Disposable Knives Injection Molds have gained huge appreciation in the market for its tough construction, fine finishing, attractive design and excellent polishing and strength.

Our Heavy Weight Polystyrene Knives have a great feature that you only get in our mould it is – High Quality Material, Crack Proof Design, Perfect Finish as per Requirement of Client, Many Sizes Available, Unique Rotary Design, Sturdy Construction, Thermal Stability, Excessive Strength, Durability and Seamless Finish. To achieve all these features we manufacture our molds with the latest manufacturing facility under guidance of an expert engineer’s team.

Manufacturing with constant investments have a higher chance of succeeding in the global market. To attain the best professional advantage, investment in MOLDEPLASTICO comes hand in hand with processes such as market development and new business processes. Manufacturing should be firm about what they plan to accomplish with business. The most successful businesses are always innovating. We are always finding new ways to build up our competitive advantages. It is necessary in boosting the vision and objectives of a business, so companies should never be reluctant to take action toward innovation.

MOLDEPLASTICO has their own in-house Research and Design center & testing facility providing the latest technology to innovate new things. This facility is allowing us to explore the limits of existing designs. We can make refinements to designs and change the materials we use to extend the limits of the technology we have already developed.

We are equipped with a technologically advanced and spacious warehousing unit. We use standard packaging material. Each article is individually packed and inspected well before dispatch. We also closely monitor the delivery of each and every mould, and take a review from every customer after successfully delivering their product.

Packaging is one of the most important step. We always use high quality packaging material to pack the mould & it’s accessories. Just as importantly, good packaging keeps mould safe during its delivery to our consumer’s doorstep by preventing our product bouncing around or getting crushed during transit.

English

English Español

Español Português

Português