Description

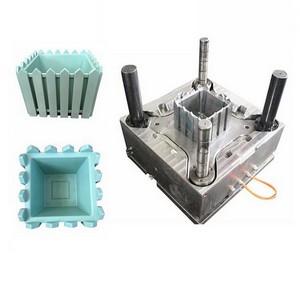

Most injection moulding manufacturer can produce plastic rattan chair mold. But to produce a good chair molding, we know that there are not many companies. If you want to know quality of chairs they produced, pay attention to the following points:

How to judge rattan chair molding cycle?

If cooling water temperature is 8-12 degree and chair weight is 1600g to 2500g, then its cycle should be 40s-55s. If machine plastics are melted and injection molded under action of accumulator, please check their waterway design. Is waterway straight? Is direction of waterway consistent with shape of chair?

How can you ensure that injection rattan chair parting line has no sharp edges?

It is dangerous to have a rough parting line on the chair. In order to avoid sharp edges, we must pay attention to many aspects in chair molding designs and mold production process: – Is design of plastic chair injection moulding parting line correct? – Is cavity core thickness sufficient? – How do you process cores and cavities? One processing or multiple processing? Normally we need three processing. From roughing to hardening of steel, we carry out the second stage of CNC milling after steel hardened. We call this stage semi-finishing. Under normal conditions, we will leave a tolerance of 0.3mm and carry out finishing after wait for stress release of steel. Machine operation at this time is very important: 1. We are going to cool in the area of CNC milling; 2. We must ensure depth cannot be greater than 0.08mm during each cutting process. All of this is to prevent steel from deforming after CNC milling and hardening of steel. Deformation can cause inaccurate assembly of core and cavity, which can result in a large amount of manual work on the mold. To do manual work in the typing area, you can’t do a perfect parting line.

How about stack of rattan chairs?

When starting chair molding designs, we have to check its superposition effect. At the same time you have to consider possibility of deformation of chair molding.

How to ensure durability of plastic rattan chair mould polishing?

In order to keep core cavity of mold from being corroded by plastic, you must ensure that steel is chrome-plated and has a hardness of more than 33. If you use some recycled materials, chair molding must be chrome-plated. Otherwise, mold should be polished frequently.

English

English Español

Español Português

Português