Description

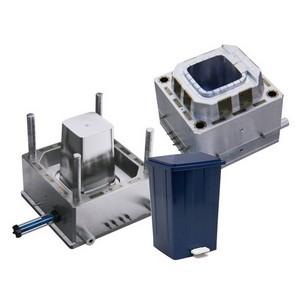

Over 15 year experience, MOLDEPLASTICO offers customers with intelligent and cost saving mold and molding solutions to their production need.

We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

We manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

We have excellent mold making lead time, some molds 50 days, some molds even 30 days, up to your parts design.

How about our design ability?

We have own design work team to design drawing according to customer's request, such as 2D&3D product drawing, or 2D&3D mould structure drawing. We are glad to share good idea for fashion design for our customer.

How can we help you improve output?

Cooling runner is most important of mold, we use "whole covering type cooling runner", you can see the blue lines in the follow 2D draft. This design allows the mold to cool more quickly, increasing throughput.

How can we ensure the quality and fast delivery?

Each mold project will be followed by an engineer who have rich experience. Engineer will make a mold schedule to ensure that every step goes smoothly, ensuring quality and fast delivery.

Adaptor Plates

The two adaptor plates serve as backing plates for guide pins, bushings and cavity blocks. The ejection end plate need not be hardened as the guide pins have practically no tendency to sink in. This plate is made of plain flat stock and cold rolled steel may be used. If it is desired to grind the plate flat, machine steel should be used, as it will not warp when the skin is removed.

The injection end plate receives more severe service, as it is the backing plate for the cavity blocks. It should be hardened. This plate has a circular mounting boss and is bored out for entrance of the injection cylinder nose. No mounting boss is shown on the ejection end adaptor, as some designers prefer to let this end float and be located by the guide pins.

A large hole in the press platen is not desirable as it weakens the platen enough to allow it to bend out of shape. On the injection end, it is necessary to have a rather large hole to allow the injection cylinder to enter as close as possible to the mold to prevent undue cooling of the plastics material as it travels through the nozzle into the sprue. So a mounting boss has been included on the injection end adaptor plate.

English

English Español

Español Português

Português