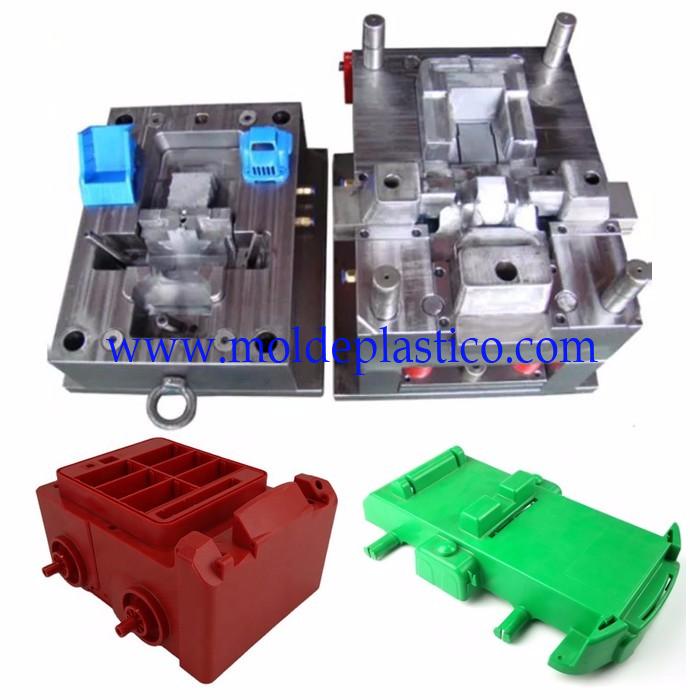

Description

We can do customized various kinds of plastic cay molds for each customer as per their requirements. The quotation can be made based on drawings or samples provided by customers. Our products are both excellent in quality and reasonable in price. Your satisfaction is our guarantee of survival!

Mould Base: LKM / HASCO / DME

Runner: Hot runner / Cold runner

Mould life: 100,000-100,0000 shots

Cavity: Single-cavity / multi-cavity

1.The part weight is from 0.1g to 1500g.

2.Molding up to 128 parts at a time.

3.The part tolerance is 0.1g of the size.

4.The wall thickness is from 0.5mm to 20mm.

5.Multi -material injection molding.

6.Plastic parts assembly capability.

7.suface treat of plastic parts

8.Provide solutions for complex parts.

Following is the essential informations, for your reference..

Mould cooling system

Optimize design cycle flow,improve production efficiency,reduce your cost.

Mould medium treatment

Adjust quality and increase hardness.

Mould post processing

The nitridation temperature is low,the deformation is small,and the surface hardness (greater than HV8500) and abrasion resistance are high without any need for quenching.

Mould life

The normal usage is not less than 600,000 die times,(4-5 million die times of bottle billet)

Mode of transportation

Before the delivery of the molds, it is necessary to install the locking film,wrap the film,and then pack the wooden box firmly to prevent rust,so as to avoid the damage during the transportation of the molds.

Delivery time

50~70days.

English

English Español

Español Português

Português