Description

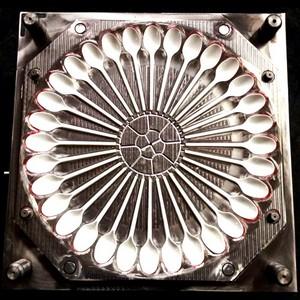

MOLDEPLASTICO is dedicated in thin wall plastic cup injection mold over 15 years experience, must be made by high degree steel like 2316 hardness, support injection molding with food material of plastic PC (Tritan), PS or SAN.

Thin wall injection moulding requires a moulding speed of 4-6S, so a very good cooling system is required. For such moulding speed, we should increase the water channel as much as possible to strengthen the water circulation.

We have a strong technical team. We have 5 senior designers and 20 engineers who has more than 15 years experiences in mould making. Our designers are good at designing new products and mould structure. In order to avoid any defects during the mould manufacturing, we usually do the mould flow analysis for the mould before we start the work on it. After mould flow analysis, we decide the mould injection gate and structure. Therefore, the mould can be finished success

We are equipped with full range of high precision machines which import from Taiwan and Japan, such as CNC, EDM, wire cutting, CMM inspection, Injection machines, etc…T here are two kinds of machines that i emphasis on, one is CNC machines for electrode machining, the highest precision for electrode we can do is 0.003mm. One is Mirror EDM which can guarantee the product precision and help to polish mold more efficiently to make the product have a beautiful shiny surface.These two machines are very expensive, many of factory don't buy them to save the cost. But we bought them in order to make better mold for customers.

English

English Español

Español Português

Português