Description

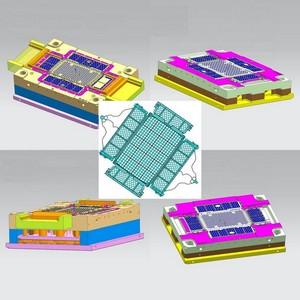

Do you need the folding crate mold with stacking mould design?

MOLDEPLASTICO can provide the highest level of skill and knowledge throughout the entire Packaging – Food/Beverage/Agricultural plastic crate mold and turnover box mould production process by consistently applying these processes.

We use hot runner technology, injection molding flow analysis software to design and make crate mould which includes:

vegetable crate mold and

plastic Collapsible crate mould

plastic non-collapsible crate mold

plastic a covered crate mould

plastic uncovered crate mold

plastic industrial crate mould (Turnover crate mould, tools crate mold )

plastic agricultural crate mold (Vegetable crate mold,Fruit crate mould )

plastic supermarket crate mould (beer crate mould,bread crate mold )

fish crate mold and so on.

Crate molds technical point

1. Choose the correct steel for mould base and mold core & cavity steel. Control the hardness of each piece of steel material, it can't be too hard

2. The moving area and guiding system of plastic crate mold must be processed by high precise machine. Any hand working is not acceptable.

3. Plastic crate mold exhaust system at the handle area is a very important subject, because when move the loaded crate, the handles area is the biggest force focused. If mold exhaust system at the handle area is not good, it will leave a visible weld, the product is very easy to damage from this point.

Advantages of Hot Runner Moulds for Plastic Crates

There are numerous advantages to using a hot runner system to make crate mould instead of a cold runner crate mould. A selection of the most obvious ones is listed below:

There is no runner system to be removed from the mold as no cold runner to be cooled, there is a shorter cycle time.

Crate Mould opening stroke is reduced.

The cost of storing and regrinding runners is eliminated.

The risk of material contamination is lower as no reground material is used.

Gates may be balanced more easily.

Hot runner diameters can be larger than cold runners; thus, lower injection pressures may be used.

Cooling times are reduced.

Better part quality can be achieved owing to a more consistent cycle.

A greater number of impressions may be used, as less injection pressure is necessary.

Smaller shot weight means shorter metering times and injection times.

Lower injection pressure means that smaller machines may be used.

These are powerful reasons for using hot runner moulds, but the crate moulds are significantly more expensive than equivalent cold runner moulds.

They are normally used for large quantities of at least 500 000 parts, but, exceptionally, smaller quantities are sometimes produced.

The disadvantages are a few but worth mentioning:

24-hour operation is required for maximum economic production.

Heat-sensitive materials may be difficult to process.

Gate blockages can be time-consuming and expensive to remedy.

English

English Español

Español Português

Português